Inkqubo yokutshisa okutshisayo ibandakanya ukusebenzisa ukushisa okuphezulu kwintsimbi yokusebenza.

Ithunyelwe nguAdmin

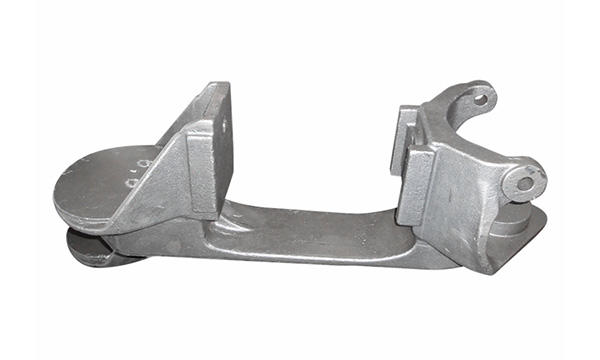

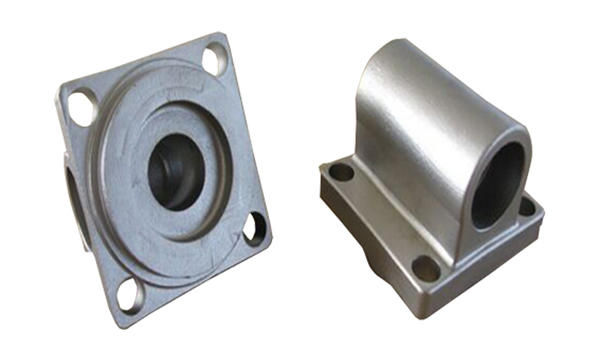

Inkqubo yokuFumana okushushuInkqubo yokutshisa okutshisayo yindlela efanelekileyo yokudala iimveliso ezikumgangatho ophezulu kunye neendleko.Nangona kunjalo, ibandakanya ubugcisa obukhulu kunye nokwenza ngokwezifiso.Ke ngoko, intsebenziswano esondeleleneyo phakathi kwabathengi kunye nabavelisi bezinto ezishushu ezishushu zibalulekile ekuphumezeni umgangatho ophezulu kunye neemveliso ezinexabiso eliphantsi.Ukubaluleka kokubandakanya umqambi kwinkqubo yoyilo kunye nophuhliso lweemveliso akunakujongelwa phantsi.Eli nqaku liphonononga inkqubo kunye neenzuzo ezinxulumene nayo.Inkqubo yokutshisa okutshisayo ibandakanya ukusebenzisa ukushisa okuphezulu kwintsimbi yokusebenza.Ubushushu obufunwayo buya kuxhomekeka kuhlobo lwentsimbi eyenziwayo.Umzekelo, intsimbi ifuna ubushushu obumalunga ne-2,100 degrees Fahrenheit, kanti i-aluminiyam kunye ne-alloys yobhedu zifuna ubushushu obuphakathi kwama-680 ukuya kuma-970 degrees.Ukushisa okuphezulu kubalulekile ukukhusela ubunzima bobunzima ngexesha lenkqubo yokuguqulwa.Ukongeza, inkqubo inokuvelisa iijometri ezintsonkothileyo ze-3D.Isebe lemveliso liququzelelwe kwiinkalo ezine ezisebenzayo:iworkshop yesiseko, ivenkile yoomatshini, ivenkile yokwenziwa, kunye nendibano kunye nendawo yovavanyo.I-Foundry lelinye icandelo lesebe lemveliso eshushu.Isetyenziselwa ukuphosa utyalo-mali okanye isanti kwisinyithi.Zombini iinkqubo zinemigca yokuvelisa kwaye zikufuphi neenkqubo ze-roller.Isebe lemveliso likwanelabhoratri yokuqhuba iimvavanyo kunye nokwenza ulawulo lomgangatho.Kukho iindawo ezine ezibandakanyekayo kwimveliso ye-forging eshushu.Kwi-Hot Forging, isiqwenga sentsimbi esilungiselelwe ngaphambili sinyanzelwa ukuba sithathe umbono phakathi kokufa kwabantu ababini.Intsimbi iya kuthatha ubume bemveliso yokugqibela kwaye inokuba nomphetho ongalinganiyo okanye ogobileyo.Ngokuxhomekeke kwinqanaba lezakhono ze-smith, le nkqubo inokuchaneka kakhulu.Ukuba i-workpiece inzima kwaye idinga ukufa okuhlukeneyo, ukubethelwa kwehamile kuya kuphinda kuphindwe kaninzi de kube yimo yokugqibela.Ukubumba okubandayo, ngakolunye uhlangothi, akufuni naluphi na ukufudumeza.Le nkqubo idla ngokuqhutywa kwiqondo lobushushu begumbi, kwaye iintsimbi eziqhele ukusetyenziselwa ukubumba ezibandayo ziintsimbi ze-carbon alloy kunye neentsimbi eziqhelekileyo.Ukubunjwa okubandayo kunokwenziwa ngokubeka isinyithi kwi-die, apho ibethelwa ngokuphindaphindiweyo ngehamile.Ihamile inokwenziwa ngoomatshini okanye isetyenziswe ngesandla.Isiphumo salo kukudala inxalenye ekulula ukuyibumba kwaye ayinakwenzeka ukuphuka.Ngexesha le-Hot Forging, i-workpiece ifudunyezwa ngaphezu kobushushu bayo bokuhlaziya,nto leyo ithintela ukuba iqine.Inkqubo yobushushu obuphezulu iphinda itshintshe isakhiwo sengqolowa ye-workpiece.Ngenxa yoko, isinyithi sigcina isimo saso esandula kuchazwa emva kokupholisa.Ikwanqanda intsimbi ekuqiniseni ukuqina, iyenze ilungele ukwenza iimilo zentsimbi ezintsonkothileyo.I-Hot forging nayo yongeza i-ductility ye-workpiece kunye nokuqina.Ngokuqhelekileyo, ukubunjwa kweemoto kwenziwa ngentsimbi.Ibe negalelo elikhulu ekunyukeni kolwakhiwo olukhaphukhaphu, njengoko i-alloys eyenziweyo ye-aluminium ithathe indawo ye-magnesium kushishino lweemoto.Ikwasetyenziselwa izinto ezininzi ezincinci ukuya kubukhulu obuphakathi, kubandakanya neentsimbi ezifana nemagnesium.Ngenxa yoko, iHot Forging ibalulekile ekwenzeni izinto ezininzi zeemoto.Ngapha koko, yeyona nkqubo ixhaphakileyo isetyenziselwa ukwenza amacandelo enjini.

Steel Cold Hot Forging Parts Carbon Steel Forgings CNC Machining PartSpecification

| into | iindawo zokubumba |

| Indawo yeMvelaphi | China Zhejiang |

| Igama lebrand | Ukucinga |

| Inombolo yoMfanekiso | KM-F001 |

| Izinto eziphathekayo | Intsimbi yekhabhoni, intsimbi yealloyi, intsimbi engenasici |

| Ubungakanani | Ilungiselelwe ngokweemfuno zomthengi |

| Iimbonakalo | OEM processing custom |

| Ukusetyenziswa | Amalungu e-Auto, oomatshini bezolimo, oomatshini bokwakha, iimveliso zetsimbi, iimveliso zentsimbi zangaphandle, iinxalenye zehydraulic |