Ukongeza kokuphonononga kunye nokuhlalutya imathiriyeli ekrwada kunye nokuphoswa okugqityiweyo

Ithunyelwe nguAdmin

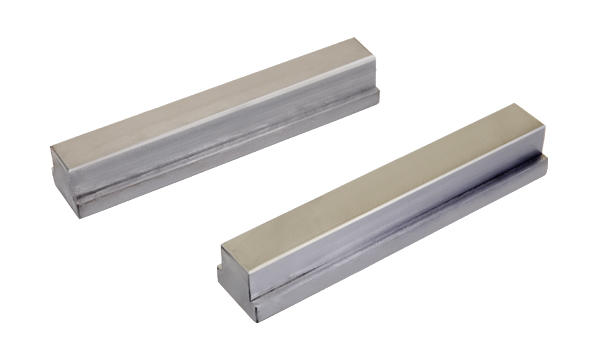

Ngokunyukayo, abathengi bafuna iinxalenye zokusa kunye nokwenza oomatshini kubaboneleli ababonelela ngelona xabiso liphantsi.Nangona kunjalo, ukunqongophala kolwazi malunga neempawu zokuphosa kunokubangela ukuba iindawo ezingasebenzi kakuhle ezinobunzima obungahambelaniyo okanye i-porosity.Kwiimeko ezinjalo, ivenkile yoomatshini inokusebenza kunye ne-Foundry ukuphucula umgangatho wokuphosa okanye unokufuna ukutyhala umthengi ukuba afumane ukuphoswa komgangatho ophezulu.Ukuze ugweme iimeko ezinjalo, ivenkile yomatshini kufuneka ifunde malunga neempawu ze-castings ezahlukeneyo.Ukulungiswa kwemodi edibeneyoUkongeza kokuphonononga kunye nokuhlalutya imathiriyeli ekrwada kunye nokuphoswa okugqityiweyo,I-LPDC ingasetyenziselwa ukwenza ngcono iiparamitha zenkqubo.Ibeka iliso kwiidatha ezininzi zexesha, ezinje ngoxinzelelo, ubushushu kunye nesichongi senxalenye, kwi-frequency yesekhondi enye kubomi benxalenye.Le datha ingasetyenziselwa ukulungelelanisa ukwenzeka kweziphene kunye nokuphucula umgangatho wenxalenye.Ngaphaya koko, i-LPDC inokwandisa iiparamitha zoomatshini, kubandakanya ixesha lokuhlala, idiameter yerim kunye nerim radius.Die casting.Inkqubo ye-die casting machining iqala ngolungiselelo lwefa.Le nkqubo ibandakanya ukucoca kunye nokuthambisa i-die, eya kunceda ukukhutshwa kwenxalenye elandelayo.Ixesha elifunekayo lokuthambisa liyakhula kunye nobukhulu benxalenye, ubunzulu bomgodi kunye nenani le-side-cores.Ngokuxhomekeke kubungakanani benxalenye, ukuthambisa kunokungafuneki emva komjikelo ngamnye.Idayi iye ibambeke ivalwe ngenkqubo eqhutywa ngamanzi aphantsi komhlabaInkqubo yokwenza isanti yomatshini iyafana naleyo yokugalela ngentsimbi.Kwenziwa umngxuma kwisanti ukwenza ubume benxalenye.Le yinkqubo esebenzayo kakhulu kumalungu asetyenziswa ngamaxesha athile kuphela.Ikwavumela utshintsho olukhawulezayo loyilo kuba iipateni zomzimba zingagcinwa kwaye ziphinde zisetyenziselwe enye injongo.Kodwa, ngaphambi kokuba wenze isanti yomatshini wokwenza iinxalenye zentsimbi, qwalasela la macebiso: CNC machiningXa ukhetha phakathi komatshini kunye nokuphosa,umthamo wemveliso uya kudla ngokuyalela indlela.Kwiiprototypes kunye nemveliso ephantsi yokusetyenziswa kokuphela komthamo, ukwenziwa kwe-machining kuya kusebenza, ngelixa ukuphosa isanti kunye ne-die-casting ziinketho ezingcono zokuvelisa umthamo ophezulu kunye nemiqulu emikhulu.Kwiimeko ezininzi, uhlobo lwenxalenye luya kugqiba indlela yokuvelisa, kunye neendleko kunye neemfuno zokusebenza nazo ziya kuqwalaselwa.Iindlela zokubuyisela kwakhona.Ubuchule bokulungisa uhlaziyo bubuchule obusetyenziselwa iinxalenye zoomatshini bokuphosa ukufa.Zisetyenziselwa ukucoca isinyithi esityhidiweyo emva komatshini.Eli nqaku lichaza ubuchule bokuhlaziya inxalenye ye-tubular die casting part.Iindlela zokubuyisela ziluncedo xa ufuna ukwenza iindawo ezininzi ezifanayo kwiprojekthi.Ubuchule bokubuyisela bubandakanya inkqubo eyaziwa ngokuba yi-degassing, enokubiza kwaye idle ixesha.Nangona kunjalo, zibalulekile ekugqityweni ngempumelelo kwayo nayiphi na iprojekthi.IindlekoIindleko zokuvelisa inxalenye inokumiselwa ngezinto ezininzi.Okukhona kufuneka umsebenzi omninzi, kokukhona ubiza ipateni, kwaye kokukhona kuthatha ixesha ukugqiba wonke umsebenzi.Ingaba inxalenye yenziwe ekhaya okanye ikhutshwe ngaphandle, iindleko zixhomekeke kubunzima boyilo, uhlobo lwezinto ezisetyenzisiweyo, kunye nenani lamanyathelo kwinkqubo yokuvelisa.Umrhumo womqhubi womatshini uqukiwe.Kwezinye iimeko, umqhubi womatshini unokukwazi ukwenza la manyathelo ngexabiso eliphantsi.UmgangathoUkwenziwa ngoomatshini bobuchwephesha obukrwada kunye nokusaswa bubeka inani lemingeni kwishishini lemveliso.Amalungu angahambelaniyo anokuba neziphumo ezibalulekileyo ukuba awenziwanga ngemathiriyeli eyaneleyo.Ukuthintela imingcipheko enjalo, abaxumi bahlala befuna iingxelo zokuhlolwa okulinganayo kuzo zonke iindawo.Ukuhlolwa kwe-Dimensional yinxalenye ephambili yolawulo lomgangatho njengoko kunceda ekuqinisekiseni ukuqhelaniswa okufanelekileyo kunye nokulungelelaniswa kwamalungu akrwada.Ngaphandle kokubaluleka kokuhlolwa kwe-dimensional, azinakwenziwa kwinxalenye ngaphandle kokujonga umgangatho.

- NGAPHAMBILI: Ukuba ujonge i-accessory yokuphucula ikhaya lakho

- OKULANDELAYO: Indlela yokuba ngumvelisi wesiseko somgangatho ophezulu