Bugu da ƙari, yin nazari da nazarin ɗanyen kayan da aka gama

Wanda aka bugaAdmin

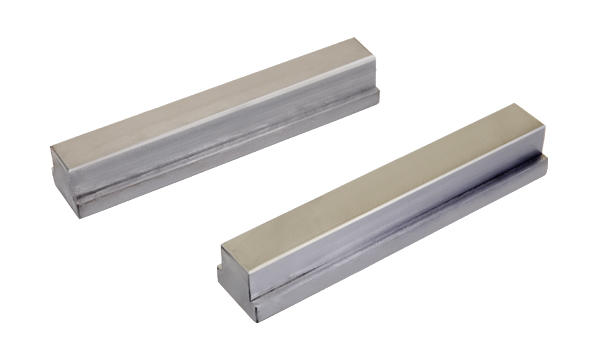

Ƙaruwa, abokan ciniki suna samun ɓangarorin simintin gyare-gyare da injina daga masu ba da kaya waɗanda ke ba da mafi ƙarancin farashi.Koyaya, rashin sani game da halayen simintin gyare-gyare na iya haifar da ingantattun wuraren injina tare da taurin da bai dace ba.A irin waɗannan lokuta, kantin injin na iya yin aiki tare da ginin don haɓaka ingancin simintin gyare-gyare ko yana iya buƙatar tura abokin ciniki don nemo mafi kyawun simintin gyare-gyare.Don guje wa irin waɗannan yanayi, shagon injin ya kamata ya koyi game da halayen simintin gyare-gyare daban-daban. sarrafa yanayin gaurayeBugu da ƙari, yin nazari da nazarin ɗanyen kayan da aka gama da simintin gyare-gyare,Hakanan ana iya amfani da LPDC don inganta sigogin tsari.Yana sa ido kan bayanan jeri na lokaci masu yawa, kamar matsa lamba, zafin jiki da mai gano sashi, akan mitar dakika daya akan rayuwar sashe.Ana iya amfani da wannan bayanan don daidaita abin da ya faru na lahani da inganta ingancin sashi.Bugu da ƙari, LPDC na iya haɓaka sigogin injina, gami da lokacin zama, diamita na baki da radius.Die simintin gyare-gyare.Tsarin mashin ɗin simintin mutuwa yana farawa tare da shirye-shiryen mutu.Wannan tsari ya haɗa da tsaftacewa da shafa mai, wanda zai sauƙaƙe fitar da sashi na gaba.Lokacin da ake buƙata don lubrication yana ƙaruwa tare da girman ɓangaren, zurfin rami da adadin ɓangaren-gefe.Dangane da girman sashin, lubrication na iya zama mara amfani bayan kowace zagayowar.Sa'an nan kuma ana manne mutun ta tsarin mai ƙarfi da ruwa. Yin simintin yashiTsarin sarrafa yashi yayi kama da na simintin ƙarfe.Ana sarrafa rami a cikin yashi don ƙirƙirar siffar ɓangaren.Wannan tsari ne mai matukar tasiri ga sassan da ake amfani da su kawai lokaci-lokaci.Hakanan yana ba da damar sauye-sauyen ƙira da sauri tunda ana iya adana tsarin jiki da sake amfani da shi don wata manufa.Amma, kafin machining yashi don machining karfe sassa, la'akari da wadannan shawarwari: CNC machiningLokacin zabar tsakanin machining da simintin gyare-gyare,ƙarar samarwa yawanci zai faɗi hanyar.Don samfurori da ƙananan ƙarancin amfani na ƙarshe, machining zai yiwu yayi aiki , yayin da yashi-simintin gyare-gyare da kuma mutu-simintin gyare-gyare sune mafi kyawun zaɓuɓɓuka don samar da girma da girma.A yawancin lokuta, nau'in sashi zai ƙayyade hanyar masana'antu, kuma za a yi la'akari da farashi da bukatun aikin.Dabarun gyare-gyaren sabuntawa dabarun ne da ake amfani da su don sassa na injunan simintin gyare-gyare.Ana amfani da su don tsaftace ƙarfe na simintin gyare-gyare bayan yin inji.Wannan labarin yana bayyana dabarar sabuntawa don sashin simintin ɗigon tubular mutu.Dabarun farfadowa suna da amfani lokacin da kuke buƙatar kera sassa iri ɗaya da yawa don aikin.Hanyoyin farfadowa sun haɗa da tsarin da ake kira degassing, wanda zai iya zama tsada da kuma cin lokaci.Duk da haka, suna da mahimmanci don nasarar kammala kowane aiki.KudiZa'a iya ƙayyade farashin kera sashi da abubuwa da yawa.Yawan aiki da ake buƙata, ƙirar ƙirar ta fi tsada, da ƙarin lokacin da ake ɗauka don kammala aikin gaba ɗaya.Ko an kera wani sashe a gida ko kuma an fitar da shi, farashin ya dogara da rikiɗar ƙira, nau'in kayan da aka yi amfani da su, da adadin matakai a cikin tsarin masana'anta.Hakanan an haɗa kuɗin ma'aikacin injin.A wasu lokuta, ma'aikacin na'ura na iya yin waɗannan matakan don ƙaramin farashiMashin ɗin ɗanyen jabu da simintin gyare-gyare yana haifar da ƙalubale da yawa ga masana'antar kera.Sassan da ba su cika ba na iya samun sakamako mai mahimmanci idan ba a kera su da isassun kayan aiki ba.Don guje wa irin wannan haɗari, abokan ciniki galibi suna buƙatar rahoton binciken girman girman kowane bangare.Binciken ma'auni muhimmin sashi ne na kula da inganci yayin da suke taimakawa tabbatar da daidaitaccen daidaitawa da daidaita kayan danye.Duk da mahimmancin dubawar ƙira, ba za a iya yin su ta wani yanki ba tare da tantance ingancin inganci ba.