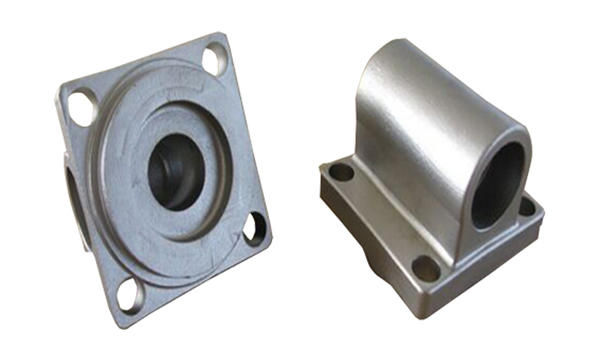

How Steel Castings Are Made

Posted by Admin

This article discusses the properties and alloying elements of steel and how they are used in making steel castings. We’ll also touch upon the costs associated with steel castings. Read on to learn more! Listed below are the different steps involved in the making process of steel castings. Once you’re done, you can go out and purchase your steel casting. Listed below are some of the most important steps involved in steel casting production.Alloying elements in steelSteel is composed of various alloying elements that improve its mechanical properties. In the austenite phase, they are nearly uniformly distributed. When the austenite is heated to the austenitic region, it tends to decompose into a mixture of ferrite and carbide. The carbide forming element prefers to go into the cementite phase. The other elements that make up an alloy are redistributed between the ferrite and cementite phases through diffusion. They also make the austenite transformation into pearlite difficult and prolong the time necessary to achieve it.Process of making steel castingsThe process of making steel castings involves pouring liquid steel into a mold and letting it freeze. At the end of the process, the tundish is almost empty and the strand has solidified. Then, driven rolls move the starter chain into a secondary cooling zone. During this step, the starter chain is disconnected from the strand and cooled. A push-out roll is then moved up into the mold and a starter chain is pulled down.Properties of steelTensile properties of steel castings are a measure of the metal’s ability to bear loads under slow loading conditions. These properties are measured by subjecting a representative cast sample to controlled tensile loading, namely pulling forces on a tensile bar until the part fails. The area of the smallest cross section after failure is the measure of the steel casting’s tensile strength. In addition to this, steel castings exhibit the same degree of toughness as their iron counterparts.Cost of steel castingsSteel castings are manufactured using a variety of processes, and many of them are subject to inspections. A representative cast sample is subjected to a controlled tensile loading. This involves applying pulling forces to one end of a tensile bar until it fails. The resulting bent bar is examined for any objectionable cracking. Another type of inspection is impact testing, which involves measuring the amount of energy required to break a standard notched sample. The higher the energy level, the tougher the cast material.Distortion of steel castingsA critical component of the quality of steel castings is their ability to resist distortion during the heat-treatment process. This process is known as annealing. The temperature range required for annealing steel castings is between 300掳C and 700掳C. This range of temperature is required for larger castings with critical stress properties. The heat-treatment process is typically done by pre-heating them and cooling them slowly once annealing is completed.