Zenziwa njani iintsimbi zentsimbi

Ithunyelwe nguAdmin

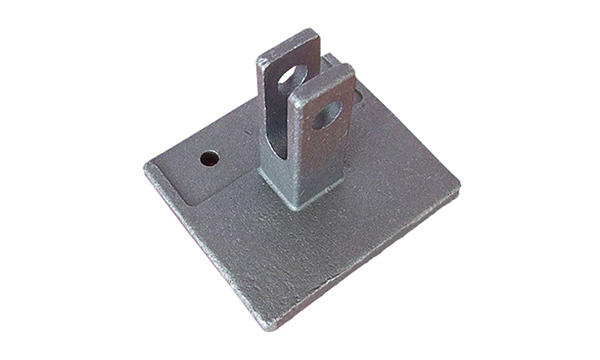

Eli nqaku lixubusha iipropati kunye nezinto ezixutywayo zentsimbi kunye nendlela ezisetyenziselwa ngayo ukwenza iintsimbi zensimbi.Siza kuphinda sichukumise iindleko ezinxulumene nokusahlelwa kwentsimbi.Funda ngakumbi ukuze ufunde ngakumbi!Uluhlu olungezantsi ngamanyathelo ahlukeneyo abandakanyekayo ekwenzeni inkqubo yokuphosa intsimbi.Nje ukuba ugqibile, ungaphuma uye kuthenga intsimbi yakho yokuphosa.Uluhlu olungezantsi ngamanye amanyathelo abalulekileyo abandakanyekayo kwimveliso yokuphosa intsimbi.Izinto zokudibanisa kwintsimbiIntsimbi yenziwe ngezinto ezahlukeneyo zokudibanisa eziphucula iimpawu zayo zomatshini.Kwinqanaba le-austenite, ziphantse zisasazwe ngokufanayo.Xa i-austenite ishushu kwingingqi ye-austenitic, iyancipha ukubola ibe ngumxube we-ferrite kunye ne-carbide.I-carbide forming element ikhetha ukuya kwisigaba se-cementite.Ezinye izinto ezenza ialloyi zisasazwa phakathi kwesigaba se-ferrite kunye nesamente ngokusasazwa.Benza kwakhona inguqu ye-austenite ibe yi-pearlite enzima kwaye yandise ixesha eliyimfuneko ukuyifezekisa.Inkqubo yokwenza iintsimbi zentsimbiInkqubo yokwenza iintsimbi zentsimbi ibandakanya ukugalela intsimbi engamanzi kwi-mold kwaye uyiyeke ibe ngumkhenkce.Ekupheleni kwenkqubo, i-tundish iphantse ingenanto kwaye i-strand iye yaqina.Emva koko, imiqulu eqhutywayo ihambisa ikhonkco lokuqalisa kwindawo yokupholisa yesibini.Ngethuba le nyathelo, ikhonkco lokuqala linqanyuliwe kwi-strand kwaye lipholile.I-push-out roll iye yanyuswa kwi-mold kwaye ikhonkco lokuqalisa litsalwe phantsi.Iipropati zentsimbiIipropati ze-Tensile ye-castings yensimbi ngumlinganiselo wokukwazi kwesinyithi ukuthwala imithwalo phantsi kweemeko zokulayisha ngokukhawuleza.Ezi propati zilinganiswa ngokubeka isampuli yommeli kumthwalo olawulwayo we-tensile, oko kukuthi ukutsalwa kwamandla kwi-tensile bar de inxalenye yokusilela.Ummandla wecandelo elincinci lomnqamlezo emva kokungaphumeleli ngumlinganiselo wamandla okuqina kwentsimbi.Ukongeza koku, ukuphoswa kwentsimbi kubonakalisa iqondo elifanayo lokuqina njengohlobo lwentsimbi.Iindleko zokuphosa intsimbiIintsimbi zentsimbi zenziwe kusetyenziswa iinkqubo ezahlukeneyo, kwaye ezininzi zazo ziphantsi kokuhlolwa.Isampulu ephoswe ngummeli iphantsi komthwalo olawulwayo wobunzima.Oku kubandakanya ukusebenzisa amandla okutsala kwelinye icala le-tensile bar de iyoyisakale.Ibar egobileyo enesiphumo ivavanyelwa nakuphi na ukuqhekeka okuchasayo.Olunye uhlobo lohlolo luvavanyo lwempembelelo, olubandakanya ukulinganisa ubungakanani bamandla afunekayo ukwaphula isampuli enophawu olusemgangathweni.Okukhona inqanaba lamandla liphezulu, kokukhona kuqina izinto eziphosiweyo.Ukuphazamiseka kweentsimbi zentsimbiIcandelo elibalulekileyo lomgangatho wentsimbi yentsimbi kukukwazi ukuxhathisa ukuphazamiseka ngexesha lenkqubo yokushisa ukushisa.Le nkqubo yaziwa ngokuba annealing.Uluhlu lweqondo lobushushu elifunekayo kwi-annealing steel castings liphakathi kwe-300掳C kunye ne-700掳C.Olu luhlu lobushushu luyafuneka kwii-castings ezinkulu ezineempawu zoxinzelelo olubalulekileyo.Inkqubo yonyango lobushushu iqhele ukwenziwa ngokuzifudumeza kwangaphambili kwaye zizipholise kancinane xa kugqityiwe ukuqhotyoshwa.