How Steel Turning Parts Can Benefit Your Industry

Posted by Admin

Steel turning parts are widely used in many industries. They ensure that machines run to their full capacity and perform at peak performance. They are also used in the manufacture of measuring equipment and medical instruments. Other applications include metal shaping techniques and automotive lathes. Read on to learn more about these parts and how they can benefit your industry.Cast steel is a versatile material that is ideal for intricate shapes and empty cross-sectional parts. It has the highest degree of adaptability and changeability among the various metals. This means that it can be customized to your specific needs. Its toughness can also be adjusted by making decisions about heat treatment and alloying elements. This will determine the degree of wear resistance it demonstrates.Cast steel turning parts can be made of different alloys for different applications. This can be based on its hardness to determine the resistance of the metal to wear and abrasion. Hardness testing is a convenient and routine way to test tensile strength in a production environment. The result of this test correlates well with tensile strength. If you are interested in getting custom-made castings, Reliance Foundry will collaborate with you to determine the ideal alloy and testing process for your applications.Traditional molding and casting techniques can be difficult to achieve in large-scale production. While traditional processes can be helpful for prototypes and low-volume parts, these processes are not as scalable as other metal processes. Therefore, they are often used as a substitute for low-volume casting or as low-volume prototypes.During the production process, castings undergo various inspections to ensure they meet the specifications. In addition to checking the material’s physical properties, they are also subject to chemical analysis to check for hidden flaws. Often, minor alloying elements can drastically affect a steel’s chemical composition, which is important for the component’s performance.Several different methods are used to manufacture cast steel turning parts. One method is hot-chamber die casting, which is the most common. Cold-chamber die casting, on the other hand, limits machine corrosion. The cold-chamber die casting process uses a steel tool to close and open the material in the die. The steel tool then ejects the part mechanically.Another process is CNC machining. This is more precise than casting and allows for a higher-quality end product. This process also eliminates the risk of casting defects. In addition to being more efficient, CNC machining can also be a cost-effective alternative. In some cases, CNC machining is the option.Cast iron is another material that is commonly used. This metal is an excellent choice for turning parts because it is a durable, wear-resistant material. It can be CNC-machined twice as fast as steel, and can be heat-treated without distortion. It also has a low cost compared to steel.

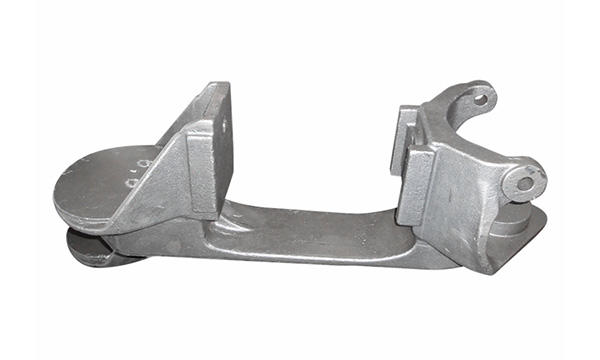

Custom Precision Stainless Steel Lathe Turning Aluminum CNC Machining Milling PartsSpecification

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M005 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |