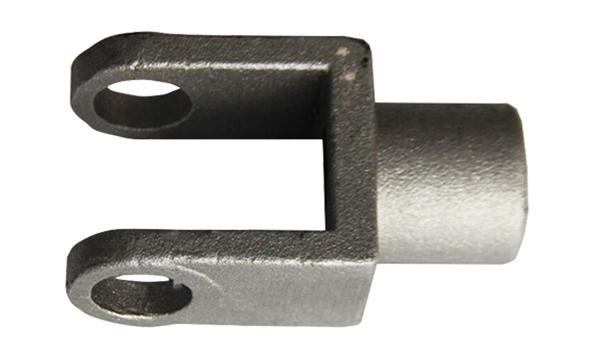

316 304 316L Stainless Steel Precision Casting Lost Wax Investment Casting

| item | steel casting |

| Place of Origin | China Zhejiang |

| Brand Name | nbkeming |

| Model Number | KM-SC108 |

| Material | Carbon steel, alloy steel, stainless steel |

| Size | Customized according to customer’s requirements |

| Features | OEM processing customization |

| Usage | Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |