How Are Cast Bucket Teeth Made?

Posted by Admin

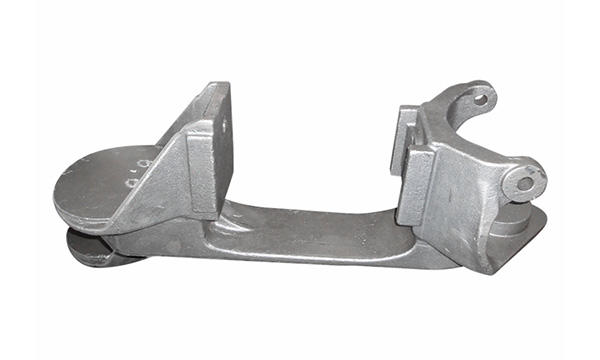

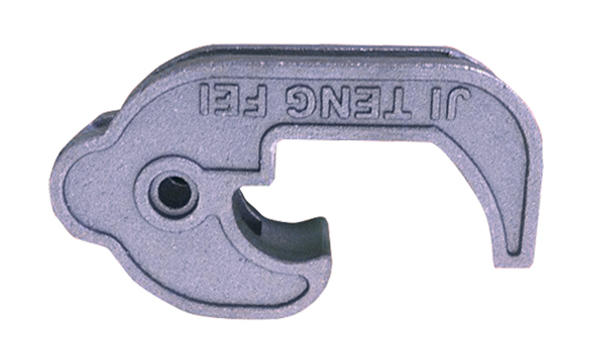

Cast bucket teeth are a component of earth-moving machines such as loaders and excavators. They are usually made of strong and durable material. These teeth are often replaced after a period of use. The materials used to manufacture these teeth can vary depending on the machine being worked.Bucket teeth are generally made of low alloy material, with a carbon content of less than 5%. This alloy has high toughness and fatigue strength. It is also suitable for a wider range of mining conditions. Compared to forged bucket teeth, cast teeth are cheaper. However, they have a shorter service life. Therefore, it is important to choose the right bucket teeth.Bucket teeth are manufactured using two main casting processes. These processes are forging and precision casting. Forging is a technique of casting metals by putting extreme pressure and temperature on the metal during the process. During the forging process, the grain flow of the steel is optimized to provide enhanced mechanical properties. In addition, forged bucket teeth have higher wear resistance and longer service life.Precision casting is a technique that is very common for the production of bucket teeth. The process involves dying design, wax pattern making, and pouring. With this method, you can control the proportion of wear-resistant parts. But, the quality of the product is inferior compared to sand casting. Additionally, the costs are moderate.Forging is an innovative process for the production of bucket teeth. Aside from improving the hardness, this process can help to increase the torsional flexibility of the teeth. Also, the forged bucket teeth are more durable and cost-effective. Since the cross-section of the forged teeth is uniform, you get a good response to the heat treatment. Besides, a forged tooth can bend almost before breaking.Before surfacing welding, it is important to preheat the bucket teeth. Otherwise, the welded seams will peel off due to the bad working environment. Moreover, it affects the production efficiency of the surfacing bucket teeth. You can increase the ductility of the forged bucket teeth by adding a wear-resistant alloy during the casting process.To ensure the quality of the product, the surface finish of the bucket teeth is very important. Besides, the wax pattern must have a high accuracy. And, it can be produced in four cores. As a result, you can save time by producing the mold only once. The main alloying element in casting bucket teeth is Mn. Various other elements are added to the casting. Usually, these include Si and carbon. When these elements are melted together, a very fine grain flow is formed. Because of this, the elongation of the material is significantly increased.Depending on the type of bucket teeth, the production process can be divided into three stages. First, you can enlist the services of a foundry for the casting. Next, you can find a machining and assembly supplier. Finally, you can finalize the buckets at your facility.