OEM processing customization

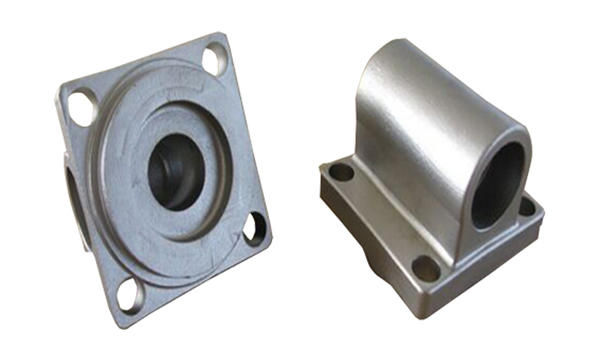

The process of forging involves various stages, including sanding, plating, and machining. The final product of the forging is a part with an accurate and precise geometry. It should also be strong and durable and last for a long time. Aside from the aesthetics of forging parts, there are several other advantages of the process. You can use them in a variety of industries. These parts can be customized for many purposes.

When compared to casting, forging parts are more durable and less prone to abrasion. Because forgings are a more solid product, post-forming processes are easier and faster. In addition, forgings offer a more smooth surface than cast parts, which makes them more effective for a variety of post-forming processes. Because of their smoother surfaces, forgings are more suitable for coating and painting.

Forging parts are stronger than cast ones, as they can be produced by the same process. The process is controlled and deliberate and can produce parts with consistent properties over many years. The advantages of forging parts include their durability and strength. With a forging, the metal can be bent or shaped to any shape, but the material must be consistent in its shape and size. If the design requires a complicated shape, you should consult a specialist. OEM processing customization

The process of forging involves various stages, including sanding, plating, and machining. The final product of the forging is a part with an accurate and precise geometry. It should also be strong and durable and last for a long time. Aside from the aesthetics of forging parts, there are several other advantages of the process. You can use them in a variety of industries. These parts can be customized for many purposes.

When compared to casting, forging parts are more durable and less prone to abrasion. Because forgings are a more solid product, post-forming processes are easier and faster. In addition, forgings offer a more smooth surface than cast parts, which makes them more effective for a variety of post-forming processes. Because of their smoother surfaces, forgings are more suitable for coating and painting.

Forging parts are stronger than cast ones, as they can be produced by the same process. The process is controlled and deliberate and can produce parts with consistent properties over many years. The advantages of forging parts include their durability and strength. With a forging, the metal can be bent or shaped to any shape, but the material must be consistent in its shape and size. If the design requires a complicated shape, you should consult a specialist.