Aluminum Die Casting is a process

Posted by Admin

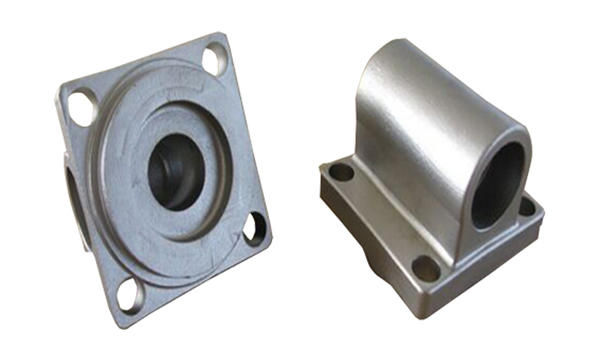

Aluminum Die Casting is a process that involves forcing molten aluminum into a mold cavity to create complex metal parts. This process is widely used in various industries, such as automotive, aerospace, and consumer goods, due to its many benefits, including low production costs, high precision, and excellent surface finishes.The die casting process involves several stages. First, a mold is created, usually made of steel, that has two halves that form a cavity where the molten aluminum is poured. The mold is designed to the precise dimensions and shape of the part being produced. Once the mold is prepared, the molten aluminum is injected into the mold cavity under high pressure using a machine.Aluminum dies casting offers several advantages over other casting methods. One of the main benefits is the ability to produce complex parts with high precision and consistency. The high-pressure injection of the molten metal ensures that the mold is completely filled, resulting in parts with excellent dimensional accuracy and surface finish.Another advantage of aluminum die casting is its ability to produce parts at a low cost. The process is highly automated, making it faster and more efficient than other casting methods. Additionally, aluminum is a relatively inexpensive metal, making it an economical option for mass production.Aluminum die casting is also a highly versatile process, as it can be used to produce a wide range of parts, from small electronic components to large automotive parts. The process can also accommodate various surface finishes, including powder coating, painting, and anodizing, making it a popular choice for manufacturers looking to create parts with a specific appearance or function.The use of aluminum in the die casting process also offers several benefits. Aluminum is a lightweight metal, making it an excellent option for parts that need to be lightweight and strong. Additionally, aluminum is highly resistant to corrosion, making it ideal for parts that will be exposed to harsh environments.However, there are also some limitations to the aluminum die casting process. The high temperatures required for the process can limit the types of materials that can be used for the mold, and the process may not be suitable for very large parts.In conclusion, aluminum die casting is a popular manufacturing process that offers many advantages, including high precision, low cost, and excellent surface finish. Its versatility and ability to create complex parts make it a favorite among manufacturers across various industries. While there are some limitations to the process, the benefits make it an attractive option for manufacturers looking to create high-quality, cost-effective parts.