The Process of Carbon Steel Casting in China

Posted by Admin

The process of carbon steel casting is the most common method used in China’s steel industry. It originated in the Ningbo area. Originally, investment casting factories used water glass as the molding material. However, water glass’s high shrinkage rate prevented it from providing acceptable precision for carbon steel precision castings. Now, most investment casting foundries use a combination molding method to ensure accuracy. The initial adhesive layer is silica sol, while water glass is used for the rest layers.The Zehan Precision Casting Foundry has been in business since 2007, with extensive capabilities in manufacturing investment castings. The company offers both small and large-scale castings. It is a partner of many benchmarking enterprises, and works with them to solve casting problems in an innovative manner. This is the way to ensure quality, cost efficiency, and delivery time.In addition to producing carbon steel castings, the company also offers a machining facility. The machining facility is separate from the casting foundry and has its own management team. The facility can machine various profiles and offers the value to its customers. The staff at the machining facility have extensive experience in product design and manufacturing.A steel casting’s tensile properties measure the strength of the material under slow loading conditions. It is measured by applying tensile forces on a representative cast sample. Typically, the representative cast sample is bent around a pin and observed for objectionable cracking. Another test for impact properties measures the energy required to break a standard notched sample.Precision castings can be produced using a variety of steel alloys. They are cheaper than investment casting and have improved repeatability and tool life. They can be used for any ferrous metal or non-ferrous metal. They can also be used to create a variety of shapes and finishes. This process allows for the manufacturing of various kinds of components, ranging from small to large scale.After steel castings are cast, the foundry performs a series of inspections to ensure that they are of high quality. This includes checking the dimensional accuracy, surface finish condition, and chemical composition. Aside from that, each piece of steel must meet a set of tolerances. Further, it should meet the specifications set by the customer.

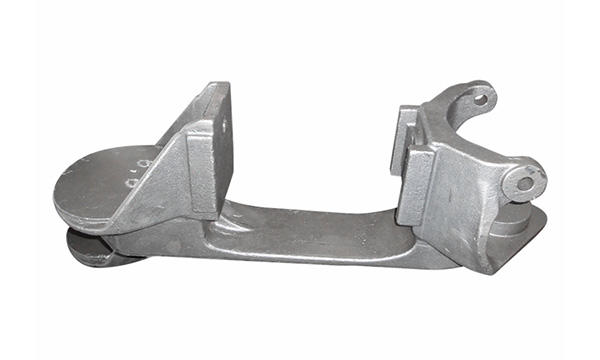

Forklift steering knuckle, left and right matching, from wax loss castingSpecification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC008 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |