How a Carbon Steel Casting Foundry Works

Posted by Admin

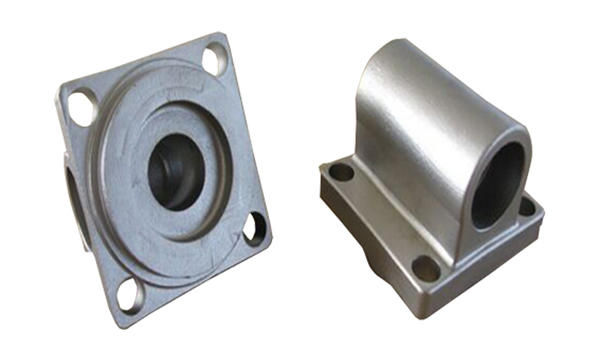

Whether you need a carbon steel investment casting or a flexible iron component, China Carbon Steel Casting Foundry can help. They have highly professional, elegant and polite employees, and their experience in product design and manufacturing is invaluable. Their expertise is often considered the key to their success. Carbon steel is one of the most popular alloys in the world. This is because it is strong and durable, and it is easily processed into any shape.Carbon steel castings can be made in a variety of different grades to achieve specific properties. In addition to this, there are several types of defects that can occur during the casting process. These defects include cracks, shrinkage, sand holes, and slag inclusion. These defects can cause a range of problems, so it is crucial to work with a company that has trained metallurgical experts. A trusted company will perform product analysis to make sure the steel is made to the right specifications.The next step is to choose a pattern. The foundry will use either a wax or foam pattern, or a metal mold. The wax or foam pattern is then fixed to a “tree” and dipped into a ceramic slurry. Once the mold dries, the wax or foam is removed. Investment casting is ideal for smaller production runs, but isn’t competitive without machining.Once the metal is ready, it is poured into a transfer vessel or ladle. This process is repeated several times, with quick adjustments in between. Carbon steel castings are commonly used for aircraft components, but the process can be lengthy and expensive. Ultimately, these parts are important to our economy. If you’re considering a carbon steel casting for your project, it is important to consider the process from start to finish.Once the steel casting is complete, it must undergo a number of inspections. These inspections assess the surface finish and look for hidden flaws. The type of pattern, mold materials, sand and mold coatings, and cleaning methods can affect the finish of a steel casting. Lastly, the tolerance level for soundness must be determined. The tolerance must be accurate and within acceptable limits. A foundry should also be able to document its tolerances in order to meet buyer requirements.The steel castings produced by a carbon steel foundry should contain more than 0.50 percent of carbon. They may also contain other elements, such as silicon, manganese, and phosphorus. These elements are what make the steel hard and brittle, and are a critical part of steel manufacturing. The materials that are made from high-carbon steel are used in the construction of many products, including airplanes, helicopters, and other ground-based vehicles.The carbon steel investment casting process involves sodium silicate lost wax casting. After the casting has been completed, it must go through surface treatment to enhance the anticorrosion performance of the steel. For example, a foundry in Taiyuan, China, has a capacity of 10,000 tons of carbon steel investment casting products per year. The Taiyuan foundry supplies parts for the marine, automotive, and electronic equipment industries. It also provides material testing for customers.

The Most Professional Casting Factory Pipe Fitting Lost Wax Parts Used in IndustrySpecification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC003 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |