The Process Capability of a Steel Casting Foundry

Posted by Admin

The process capability of a Steel Casting Foundry is critical to the successful production of the components used in the manufacturing process. Tolerances vary based on the quality of the pattern, mold material, pre-machining, and straightening. To ensure dimensional accuracy of the finished part, the foundry must control and document the casting process. In addition, many alloys that must be used in severe applications cannot be wrought, and the foundry must know how to produce these materials to meet specifications.Modern steel casting technology uses a variety of furnaces to create precision molds and components. The first method, known as metal molding, involves the use of refractory materials and a catalyst. This process creates products with high surface accuracy and an excellent surface appearance. This method is particularly suitable for manifolds and turbine blades. The second method, known as electric arc furnace (EAF), uses an electric arc furnace to melt steel. This process is able to refine the metal to the required quality for the part to be produced.Another type of steel casting is alloy steel. This material contains a minimum of 11% of chromium, which prevents the iron from rusting. It is then filled into a mold using liquid steel. Ductile iron, on the other hand, has excellent ductility and wear resistance. This type of cast steel is commonly used in the manufacturing process. In addition to the above, the iron also has a ball shape.Whether the metal is a castable material or a molded part, the process of casting is a complex one. Regardless of its shape, experienced foundries can create almost any shape or design. Internal holes are as easy to cast as external ones. A skilled foundry can even control the amount of shrinkage. Melt-solidified metal will contract when frozen, so long slender parts will shrink faster than long, rounded parts.Whether you’re working in a steel casting foundry or a car engine, metal transportation is a significant part of the process. Taking proper precautions will keep you and your equipment safe. Additionally, you’ll have to lift heavy objects. The process requires coordination, which is important for worker safety. In addition to manual dexterity, you’ll need to have basic knowledge of power tools and how to safely operate a forklift.Health hazards posed by a Steel Casting Foundry are many. Dust, fumes, metal dust, and acids are just a few of the factors that pose risks to workers. The foundry’s high ambient temperatures and intense heat conditions make working in a foundry a risk for health. As a result, proper safety and health practices are essential for the production of quality parts. But safety precautions do not end there.

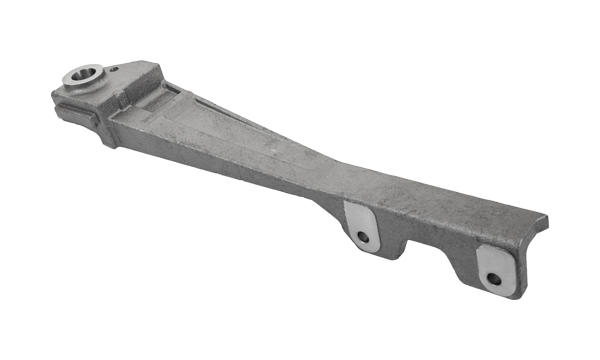

Farm Implements Agricultural Machinery PartsSpecification

|

item |

steel casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-SC010 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |