The process of Aluminum Die Casting is a highly versatile metal fabrication

Posted by Admin

Aluminum Die CastingThe process of Aluminum Die Casting is a highly versatile metal fabrication. It can produce various metal parts, including a variety of automotive components. The material has excellent corrosion and wear resistance, and is suitable for a variety of applications. Various alloys are available to meet a variety of specifications. Sunrise Metal is one such company. Here, you can be sure of getting a high-quality product delivered on time. For more information on Aluminum Die Casting, please check out our website.The process begins with pushing the two dies together. The temperature is between 120 degrees and 280 degrees Celsius depending on the part to be produced. The molten metal is injected at high pressure, typically between 1,500 and 25,000 psi. The molten metal flows along the runners in the die and passes through a gate to form the desired part. The dies then cool the molten metal to a low temperature before it is ejected.Aluminum die casting alloys A380 and 383 are the most common, as they offer a good combination of physical and mechanical properties. The material is light and easy to cast, and it has excellent corrosion and heat resistance. Its thermal conductivity and electrical conductivity are among its characteristics. It is also highly ductile, making it useful for high-pressure applications. Likewise, the material is easier to machine. It is also available in various alloys.For the midrange to large die castings, aluminum is the preferred metal. This metal has a very high specific gravity of 2.7, making it one of the most flexible metals known to man. Furthermore, aluminum is stable even at high temperatures, which makes it an ideal choice when it comes to long-term benefits. There are three basic alloys for aluminum, and these constitute the bulk of aluminum die casting. So, what alloy is right for your application?The advantages of Aluminum Die Casting are numerous. For instance, compared to other manufacturing processes, it is cheaper to produce complex 3D parts, allows for minimal machining and finishing, and is ideal for mass production. Further, it is easy to create lightweight constructions. If you have an industrial project, you can use aluminum die casting for your project. Its high-strength aluminum material is corrosion-resistant and is also lighter than most other metals.Aluminum Die Casting is an industrial process that involves injecting molten aluminum metal into a mold cavity. Aluminum die cast alloys have excellent corrosion resistance, good mechanical properties, and excellent electrical and thermal conductivity. Because they are more malleable than cast aluminum, they are more durable and can be fabricated into a variety of shapes. For instance, an aluminum car body has a higher weight-to-volume ratio than a similar steel one.

Aluminum cast fire hydrant quick connectorSpecification

Aluminum cast fire hydrant quick connectorSpecification

|

item |

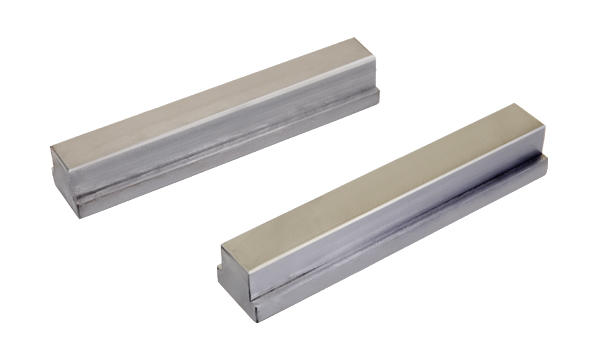

aluminum die casting |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-A001 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |