There are many types of bucket teeth

Posted by Admin

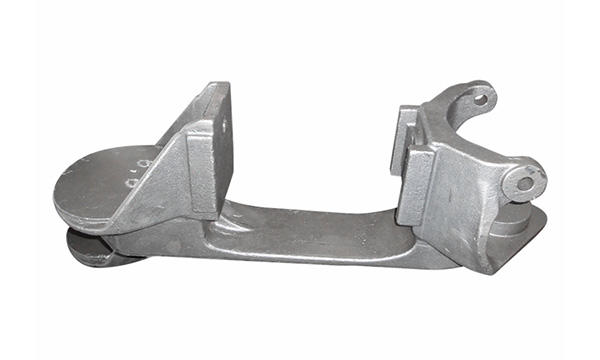

There are many types ofbucket teeth.Some are broad and blunt while others have sharp points. Their shape and size determine how much material they can penetrate. Wide teeth are good for general loading and excavating while sharp teeth are for trenching and breaking up hard ground. Depending on the job, a particular type of bucket tooth may be better suited for the application. Bucket teeth can also be self-sharpening to maintain their efficiency.Typical Bucket Teeth are made from carbon or alloy steel.Forged teeth are made from higher-quality materials such as nickel or chromium steel. The forged teeth have higher tensile strength than standard-duty ductile iron teeth. These bucket teeth are used on a wide variety of machines. They can also be used for different materials such as clay and hard stone. But if you are looking for a very tough bucket, choose one with a chisel-edge.There are many different types of bucket teeth on the market.You can select one with the right characteristics for the application.Its strong curved shape is designed for good penetration in various abrasive materials, such as rock and compacted soil. Likewise, the Tiger (TG) tooth offers maximum penetration into hard-packed clay and rock. If you are looking for a bucket tooth that will fit a specific application, consider choosing one with Twin Tiger (TT) teeth.Choose Quality Bucket TeethsMining excavators have a crucial role in the construction industry.Mining excavators are common tools used to extract minerals, and their bucket teeth are often the most worn and damaged parts. Ultimately, they can help make a difference in the efficiency of work and reduce downtime. A good bucket is essential for the advancement of society and the engineering world. There are several advantages of bucket teeth. So, make sure you buy them with care!An excavator bucket teeth can have different hardness levels.A hacksaw will be able to cut bucket teeth of different hardness levels. Most common materials used for excavators include low carbon steel and high chromium cast iron series. The latter offers good toughness and impact resistance, while the former offers low machinability. Low-carbon martensitic steel is between the two and has good processing performance.

Excavator Bucket Excavator Bucket Parts Excavator Bucket Teeth

Specification

|

item |

Bucket teeth |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-B003 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |