When it comes to stainless steel, the surface finish plays a key role

Posted by Admin

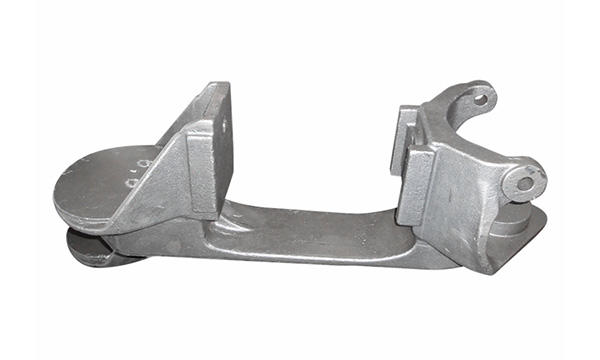

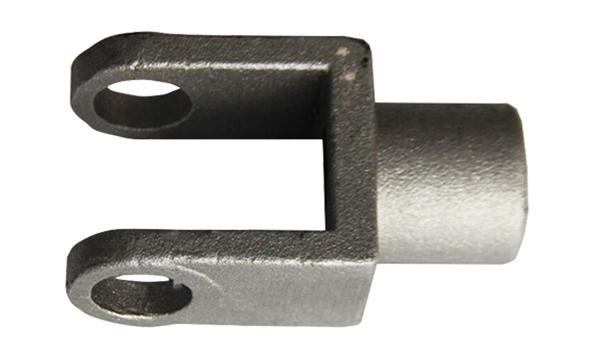

The Advantages of Using SS Steel Casting ManufacturersStainless steel is an alloy composed of iron and carbon. It has a high level of resistance to corrosion and is easily shaped. As a result, it is widely used in construction, appliances, and appliances. It can also be molded easily, and is produced in large quantities. Listed below are the benefits of using high-quality stainless steel casting. To learn more, read on! SS Steel Casting ManufacturersStainless steel is an alloy consisting of iron and carbonSteel is a very versatile material. It is composed largely of iron, which is only slightly harder than copper. Steel is also polycrystalline, which means it contains many different crystals. Crystals are well-ordered arrangements of atoms in a plane, usually a cube. The iron lattice arrangement is described by a unit cube with eight iron atoms on each corner. One of the most important properties of steel is its allotropy, or ability to exist in two crystalline forms.Stainless steel is a very versatile material. Stainless steel has a high chromium content, making it an excellent choice for a variety of applications. Each type of stainless steel contains a different percentage of nickel or chromium, giving it different properties. In addition to its high chromium content, stainless steel can be shaped into various shapes, such as wire, plates, and bars.It is resistant to corrosionA number of different types of metal are corrosion resistant, and each type has its own advantages for particular applications. Each type also differs in price and properties. When most people think of corrosion resistance, they immediately think of stainless steel. This type of metal is the most widely used, but there are different types and each one has a specific range of qualities. If you are planning to use stainless steel in a particular application, here are a few reasons why:Aluminum is an excellent corrosion-resistant metal, and it is widely used in harsh environments. When exposed to oxygen, aluminum forms an aluminum oxide layer. Aluminum oxide is much stronger than aluminum itself, and it protects the rest of the metal. In contrast, iron oxide flakes off, allowing more iron oxide to form. Consequently, a piece of aluminum made from titanium is more durable and will not corrode as easily as steel.It is easy to shapeStainless steel casting is a process used to manufacture parts. It is an ideal option for a wide range of applications, including the manufacture of structural components. The process can be carried out in several ways, including hot or cold rolling, or extrusion. The final step of the process is cold rolling, which reduces the thickness of the steel. This preparation prepares the steel for further processing. There are a variety of advantages to stainless steel casting.Stainless steel is a metal alloy with iron, carbon, and chromium as the main constituents. The stainless steel content is about 10%, with the rest of the mass made up of iron. The corrosion resistance is attributed to the chromium content, while molybdenum is a unique minor component. Molybdenum is a distinctive chemical that adds to the corrosion resistance of the stainless steel.It is produced in large quantitiesMany of the stainless steel castings in China are produced by small Chinese companies. However, this practice is becoming less prevalent, as most customers opt for larger companies that produce stainless steel castings in bulk. It is important to note that the cost of stainless steel castings is affordable, and the price of molds is very cheap as compared to the quality of the finished products. If you’re considering ordering castings in bulk, it is recommended that you select a small-scale China SS steel casting manufacturer.When it comes to stainless steel, the surface finish plays a key role. Some finishes improve the resistance to corrosion, and are more hygienic for sanitary applications. Others, however, are used in lubrication applications. Other finishes include the taper face, which is a vertical surface that encloses a pattern. Hollow gaps, which are formed within a casting, can be used as a replacement for draft.