CNC machining is a popular method for manufacturing metal parts

Posted by Admin

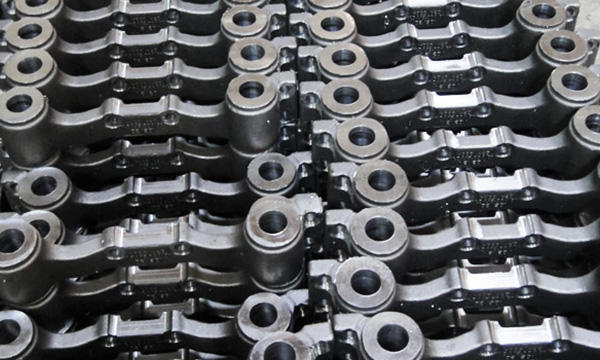

Post-Processing Methods for CNC Machining PartsCNC machining is a popular method for manufacturing metal parts. A CAD file of the part can be uploaded for Manufacturing Analysis. This software will provide a quote based on the material and quantity you have selected. You can also change the quantity and materials as you wish with real-time pricing updates. It also lets you choose threading and other special features, if any. With CNC machining, you can save time, money, and efforts by using the software.Materials used in CNC machiningThe materials used for CNC machining vary widely. Brass, for example, is inexpensive and easy to machine. It has excellent strength-to-weight ratio and is corrosion-resistant. In addition to its low-cost properties, brass is highly formable and machinable, making it an ideal choice for many applications. But, there are other metals that are equally well suited for CNC machining. Brass is a versatile material that is resistant to heat, corrosive materials, and salt.Plastic materials can also be processed through CNC machining. Nylon powder, metal powder, and sandstone powder are some common materials. CNC machines can also process plastic plates and general hardware. However, they are not as dense as 3D-printed parts. Hence, the right material for CNC machining is critical. Consider the materials used in CNC machining before purchasing any machines. This will help you select the most suitable CNC machining tools and equipment.TechniquesVarious post-processing methods are available for CNC-machined parts, ranging from sanding to electroplating. While sanding is usually the last step in the machining process, some parts may require other post-processing methods. These methods are used to achieve different surface roughnesses on parts. Listed below are some common post-processing techniques. These methods can be helpful for different applications and may be a good alternative for your CNC-machined parts.Level the base – A non-level base can result in high stress on the parts, resulting in poor repeatability. Using a three-plane laser or a machinist’s level can help ensure a perfectly level base. In addition to leveling the base, you can also use the square bridge technique, which involves creating a perpendicular axis between X and Y.ToolsThere are many different types of CNC machining tools. Some of these tools are more common than others, and some are more complicated than others. End mills, for example, are tools that remove material from a workpiece by removing its material layer one at a time. Unlike drill bits, end mills do not need to be pre-drilled holes to use them. In addition, the flutes on end mills are serrated, making it possible to remove larger amounts of material.The Manufacturing Analysis tool allows you to import a 3D CAD file and calculate the exact amount of material and quantity required to create the part. You can even change materials and quantities right there in the software, and see real-time pricing updates as the process moves forward. You can even assign threading to your parts if you need to. In a matter of seconds, you can view the threading on your parts and get an accurate price.ChallengesCNC machining is a vital part of many manufacturing facilities today. This technology allows for a variety of different component designs, both complex and simple. But CNC machining is not without its challenges. These challenges include ensuring the correct set up and programming of CNC machines, as well as the need for skilled operators. In order to overcome these challenges, CNC operators should have the necessary technical skills, managerial and programming skills. Listed below are a few of the more common challenges that CNC operators face when they are creating CNC machining parts.Exotic materials are challenging to machine, and aerospace components frequently require specialized materials. These materials are not readily available, making them particularly expensive to source. Other materials that can pose challenges include glass-filled plastics and superalloys. Additionally, the materials can be expensive to ship. But the advantages of CNC machining for aerospace parts far outweigh these disadvantages.