What Is Hot Forging?

Posted by Admin

During hot forging, a preformed metal is forced into an impression between two fixed dies. The force and temperature are determined by the size and geometry of the part being forged. The net weight of the original metal is about the same as the weight of the finished product. The process can be automated.Unlike cold forging, hot forging is characterized by high temperatures. This allows for more precise adjustment of the microstructure of the metal. Because of this, the strength and ductility of the metal are greatly increased. In addition, the temperature of the work piece can be higher than the recrystallization point, which prevents strain hardening during the deformation. It also decreases the flow stress of the material. This reduces the energy required to form the metal. In fact, the deformation degree can be significantly higher than in cold forging.Forging is a process that is commonly used in the automotive and aerospace industries. It can be used to produce parts in a wide range of materials. For example, it can be used to make components in iron, steel, aluminum, and titanium. It can be used to produce different types of components, such as gear blanks, bearing races, and gears. The parts produced by this process can be complex in shape, so machining is always required. In addition, forging is a highly economic process, as it requires little finishing.There are several types of equipment used to perform hot forging. Some are machine shops, while others are foundry workshops. These machines have the capability to handle a large number of forgings in a short amount of time. This makes it possible to create complex parts in a quick and efficient manner. In some cases, these processes can be used to produce forgings up to 3 meters in length.It is important to select the right hot forging process for your manufacturing needs. Because of the increase in costs of the industry, the right process is essential. It is important to consider the complexity of the item being forged and the costs of the raw materials. In addition, the forging allowances must be calculated. Typical forging allowances can range from tenths to several millimeters. If the allowances are not accurate, then the forging may not be able to be produced as desired. This can result in rework or scrapping.Hot forging has been around for many years. It has a special place in the manufacturing world. The technology can provide parts with superior mechanical properties, and it can produce parts with low waste material. Forging is used for processing metals that are difficult to form. It has been used to create parts with 3D geometries. Some examples include large-scale integral components of Ti-alloy and complicated blades. The metal is also stronger and more ductile than cast parts. This has made it a popular method for producing safety components.Hot forging is also used to produce parts in a variety of other industries. It is also a more economical alternative to other forming methods, such as cold forging.

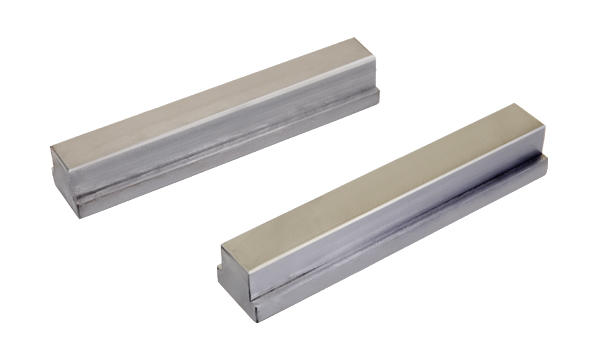

Forging block and subsequent machining

|

item |

forging parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-F002 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |