Types of Precision CNC Machining Parts

Posted by Admin

A precision CNC machining part is an intricately designed, highly functional component. These parts can range from stamping to brass turn. High volume production runs require highly accurate parts, and many types of CNC machining tools can deliver exactly the desired result. In addition to machining parts, precision CNC machining can provide companies with in-house toolmaking services. Here are three types of CNC machining projects. These projects can be complex, or they may be simple and straightforward, depending on the part.High precision machining is critical to the success of any product or service, from the medical industry to the manufacturing industry. High-quality precision CNC machining parts are able to deliver components with extremely tight tolerances, typically 0.00508 mm to 0.0005″. Moreover, precision CNC machining can also provide exceptionally smooth surface finishes, due to advancements in servo control technology. These factors make precision CNC machining part manufacturing an essential tool for businesses today.In addition to a precision CNC machining part, precision CNC machining manufacturers also care about accuracy and tolerance. Improper processes can increase the number of scrap parts and rework cycles, costing a manufacturer time and money. Moreover, fancy new measurement systems require time and attention to calibrate and set up. These factors add to the cost of precision CNC machining. And, the more accurate a CNC machining part is, the more accurate and reliable it is.The process of machining is a complex process that requires the use of various cutting tools. The precision of CNC machining is enhanced by the use of computer numerical control (CNC) software. This type of machining allows the material to be cut and shaped precisely to the part specifications. The CNC controller reads a programming code that allows the equipment to perform specific functions. Afterwards, the equipment cuts the material into smaller parts, and the process continues until the required mechanical, medical, or industrial part specifications are met.A CNC milling machine uses a multi-axis feature to produce complicated geometries in a single operation. Its high-pressure coolant prevents chips from entering the workpiece, which reduces the possibility of operator error. A CNC milling machine has multiple axes and differs in size, number of axes, feed rates, and cutting speed. This type of precision CNC machining has many advantages over conventional machining methods.A precision CNC machine can be extremely precise, reducing the need for human error and ensuring that the part is precisely manufactured. A CNC machine can also maintain lower setup and production costs. The overall accuracy and repeatability of precision CNC parts are unmatched. The ability to perform this task with less manual intervention is another reason why it is so successful. Most CNC precision machines require minimal maintenance, making them the choice for high-volume production.Another type of precision CNC machining is turning. This type of process entails rotating a workpiece next to a single-point cutting tool. Common turning tools include engine-purpose lathes, turret lathes, and taper lathes. Taper turning and straight turning are other popular types of precision CNC machining parts. A multi-axis machine can be used to perform more complex tasks.

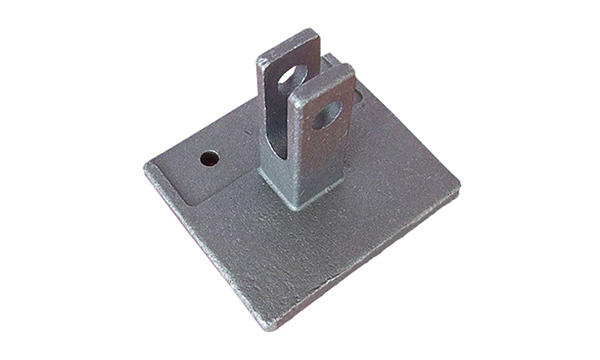

CNC Machining Turning Custom CNC Stainless Steel Part Mountain Bike PartsSpecification

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M006 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |