The Importance of Precision CNC Machining Parts

Posted by Admin

One of the most important aspects of a Precision CNC Machining Part is the level of precision. Precision is defined as the ability to reproduce attributes that are consistent across a large number of produced units. As such, it is essential to keep tolerances within acceptable limits. In many cases, machining a part that is outside of tolerances can result in an inaccurate part.Precision CNC machining processes are capable of handling high volume production runs while maintaining tight tolerances. This enables the production of a variety of production parts, including parts that are used to build machines and appliances. Precision CNC machining is ideal for the manufacture of high-quality precision components for medical devices and other products.CNC machining is a cost-effective, high-speed process that can be used for a wide variety of applications. CNC machining machines are flexible enough to work with a wide range of materials. They are especially compatible with various kinds of plastics. As a result, these machines are ideal for producing high volumes of parts.The importance of precision machining cannot be overstated. From the automotive industry to consumer electronics, precision parts are required. Even the smallest of details are critical, and a mistake could lead to disastrous results. This is why Precision CNC Machining Parts can be crucial for manufacturing processes. Precision CNC Machining is the way to ensure that all parts of your product are made according to your specifications.CNC machining allows you to produce intricate geometries in a single operation. This helps to reduce human error and saves you money. Multi-axis CNC machines can also perform more complex tasks such as drilling, tapping, and boring. They allow you to specify exact dimensions by entering blueprint specifications into the CNC machines.Precision CNC machining tools are highly accurate. However, they cannot reproduce all dimensions exactly as the CAD blueprint. To compensate for this, machinists use tolerances. Tolerances are defined as the range of deviations between the desired dimensional size and the actual dimension that can be tolerated. Tolerances are not universally enforced and the strictness of measurement depends on the process.Precision CNC Machining parts are used in commercial and industrial applications to produce high-quality parts with tight tolerances. They are especially useful for products that require interworking. In addition to being more accurate, Precision CNC Machining parts are also faster to produce. Furthermore, they are more cost-effective than traditional methods.A Precision CNC machine shop can use a variety of tools to create parts with interesting features. For instance, drilling is a common process in a precision machine shop. The process begins with a smaller starter hole, which is then enlarged. This step is often performed before the final finishing operations.

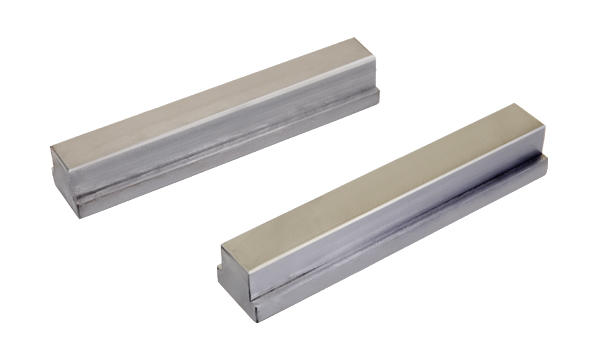

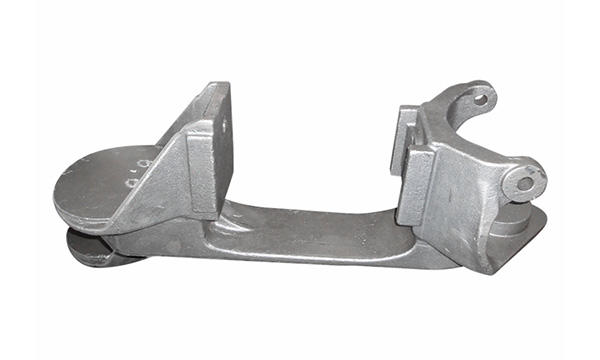

Customized High Precision Aluminum Stainless Steel Brass Steel Motorcycle CNC Machining Parts for Testing Equipment

|

item |

machining parts |

|

Place of Origin |

China Zhejiang |

|

Brand Name |

nbkeming |

|

Model Number |

KM-M004 |

|

Material |

Carbon steel, alloy steel, stainless steel |

|

Size |

Customized according to customer’s requirements |

|

Features |

OEM processing customization |

|

Usage |

Auto parts, agricultural machinery, construction machinery, metal products, outdoor metal products, hydraulic parts |