If you’re looking for an accessory to enhance your home

Posted by Admin

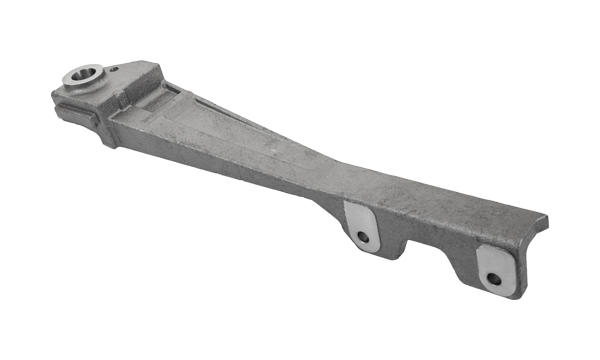

Different Types of Bucket Teeth BarsIf you’re looking for an accessory to enhance your home, consider a Bucket Teeth Bar. These accessories are an excellent choice for any interior design project. The style you choose will depend on your style, but there are several different types available. Bucket teeth bars come in different types, including Forged, Cast, XS(tm), and Twin Tiger. Here’s some advice to help you select the right one for your project.Forged bucket teeth are more durable than cast ones and are made of heat-treated alloy steel. Forged teeth are also more lightweight and can be self-sharpening. However, their durability and toughness is not as high as those of forged bucket teeth. Therefore, forged bucket teeth are more expensive. This article will discuss some advantages and disadvantages of forged bucket teeth. A comparison of forged and cast bucket teeth is also provided.Using cast-in bucket teeth is a new technology that is quickly becoming popular. The process involves the use of two firm metals to create the tooth tip and inserting a prefabricated block of wear-resistant material into the bucket. The results are bucket teeth with excellent wear resistance, impact toughness, and hardness. Unlike other casting processes, however, the process is relatively simple. While the process does require some planning and care, it can still result in a low bonding strength.This system is durable and cost effective, resulting in maximum performance and productivity. The hammerless fastener system is reusable, providing cost-efficiency while promoting safety. In addition, the XS System features a streamlined, unique tooth design.If you’re looking for a rock chisel for bucket teeth, look no further. This rock chisel fits CAT J450/460 buckets and is a direct fit. It maintains its sharp edge throughout its life, improving the bucket’s performance and lifespan. Note: The name of the manufacturer and the symbol ‘PM’ in the part listing do not imply endorsement or affiliation with that company.A common way to improve the lifespan of a bucket is to rotate its teeth. The lower edge of the bucket teeth typically wear out faster than the rest. Rotating the bucket teeth will result in better wear and less damage to the adapter nose and teeth. The teeth are generally made from high-grade metal, such as steel. A rotating bucket tooth can also help prevent poor contact when the teeth of a new bucket are installed. Rotating bucket teeth can help extend the life of a bucket by a significant amount.The design of bucket teeth must ensure high impact resistance. During the excavation process, the teeth will come into contact with the object. The higher the speed, the higher the impact load. The lower yield strength of bucket tooth material will result in plastic deformation at the tip. This wear-resistant material will also be affected by the depth of excavation. This article will focus on the application of wear-resistant surfacing. It can also prevent the teeth from breaking when the digging depth increases.The cost of bucket teeth and tips varies according to material, manufacturing process, and application. Advanced manufacturing techniques and the use of high-quality material are expected to drive the market during the forecast period. Changing geopolitics, in particular, can act as a restraint. However, these restraints may be overcome with innovative technology and improved raw materials. The cost of bucket teeth and tips is estimated to be around $18 billion by 2025.