Casting with mirror polishing is a process

Posted by Admin

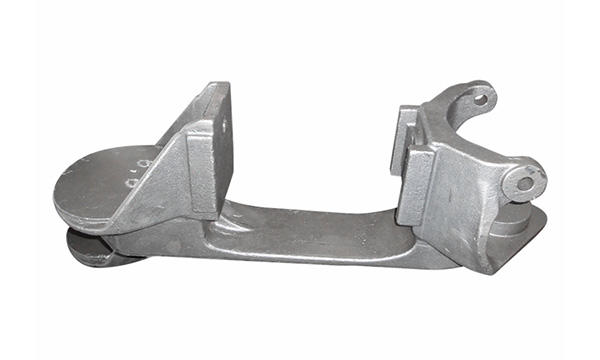

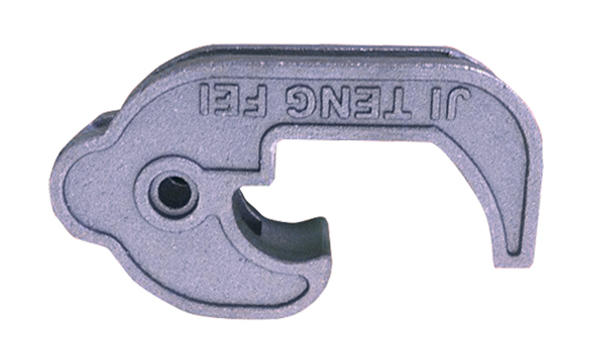

Casting is a manufacturing process that has been used for centuries to produce complex metal parts. One of the challenges of casting is achieving a high-quality surface finish on the cast part. Mirror polishing is a technique that can be used to achieve a smooth and reflective surface on cast metal parts. In this article, we will explore the process of casting with mirror polishing, the benefits of using this technique, and some tips for achieving the results.Casting with mirror polishing is a process that involves casting the metal part using a high-quality mold and then using a series of polishing techniques to achieve a mirror-like surface finish. The casting process is typically done using a two-part mold that is made from high-quality materials such as silicone or steel. The mold is designed to create a part that has a smooth surface and is free from any imperfections.Once the part has been cast, it is then removed from the mold and subjected to a series of polishing techniques. The first step is typically to use a coarse abrasive material to remove any rough spots or imperfections on the surface of the part. This is followed by a series of finer abrasive materials that are used to create a smoother surface.Once the surface has been smoothed, a polishing compound is applied to the surface of the part. The compound is typically made from a combination of abrasive materials and a lubricant, which helps to create a smooth and reflective surface. The part is then polished using a series of soft cloth or felt wheels that are used to buff the surface of the part to a high shine.There are many benefits to casting with mirror polishing. One of the main benefits is that it can be used to create parts that have a high-quality surface finish. This can be especially important for parts that will be visible to customers or that will be used in applications where the surface finish is important for functionality. Mirror polishing can also be used to create parts that have a decorative finish, such as metal sculptures or architectural elements.When casting with mirror polishing, there are a few tips that can help to achieve the results. First, it is important to use high-quality materials for the mold and the casting process. This can help to ensure that the part is free from imperfections and is easy to polish. It is also important to use a series of abrasive materials that are appropriate for the type of metal being cast. Finally, it is important to use a high-quality polishing compound and to use a consistent technique when buffing the surface of the part.In conclusion, casting with mirror polishing is a technique that can be used to create high-quality metal parts with a smooth and reflective surface finish. The process involves using a high-quality mold, a series of abrasive materials, and a polishing compound to create a mirror-like surface on the part. By following the tips outlined in this article, it is possible to achieve the results and create metal parts that are both functional and aesthetically pleasing.