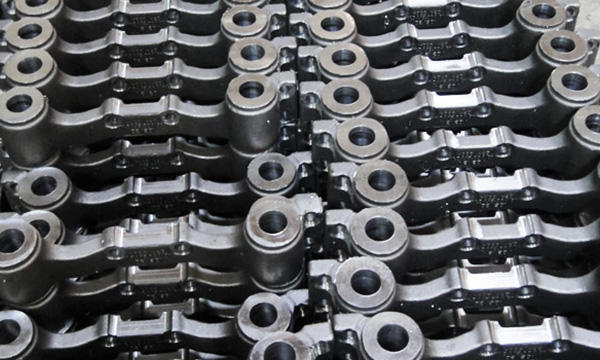

Carbon Steel Lost Wax Casting in China

Posted by Admin

The carbon steel lost wax casting process produces high-quality parts with complicated shapes. Compared to other casting processes, this one is the most economical and suitable for complex shaped parts. However, it requires a surface treatment to make it corrosion resistant. Companies such as Taiyuan Simis can produce up to 10,000 tons of carbon steel investment cast each year, ranging from the automotive industry to the marine industry. Here are a few advantages of this process.Firstly, the carbon steel lost wax casting process is based on the use of water. The process has a high degree of control over the material, and can produce a CT5-CT8 tolerance for carbon steel. Moreover, the production cost of water glass casting is low, making it the preferred choice for most manufacturers. The carbon steel lost-wax casting process is also known as silica sol casting.The water glass casting process is a cost-effective way to manufacture carbon steel castings, and most of them are made using this method. In China, water glass casting is the most popular method for producing carbon steel parts. It also has a higher degree of control over the carbon content in the casting, but this method is expensive. Therefore, only a few foundries in the world use it. As of now, water glass casting is the option for carbon steel investment castings.The water glass casting method is another alternative. It produces carbon steel castings with a tolerance of CT5-7. It is also highly reliable, but the production cost of water glass casting is high. As a result, it is not recommended for many applications. The cost-effective method of 1045 carbon steel lost wax casting is preferred by most customers. In addition to this, it has an extremely high tolerance of quality and durability. If you are interested in learning more about the benefits of this process, you should learn more about the different casting methods.This highly engineered carbon steel casting is used in more than 90 percent of durable goods. It is commonly found in vehicles, machinery, and wind turbines. It is also used in medical and defense products. Despite its low cost, carbon steel lost wax casting is a cost-effective solution, but it does not guarantee the highest quality.Besides being a cost-effective method, it has many advantages. It is an excellent solution for complex parts that require high tolerances. It is a high-quality process that is highly accurate, and the resulting products are highly durable. This process has been used for thousands of years in China, and it is an effective way to produce parts for various industries. As a result, it is ideal for medical devices. It can also be used for aerospace components.It is a high-quality carbon steel investment casting process. Its tolerance CT7-CT8 is very high and it is preferred for manufacturing carbon steel components. It is also the most economical method and can be used for low-cost products. A high-quality product may not be a good solution for your application. It should be made of high-quality materials with a high-quality surface finish. You can find many types of investment castings in the market, including a carbon steel lost wax cast.This is a cost-effective and reliable method, and is used for parts with complex shapes. Unlike the lost wax casting process, it can produce parts with close-to-net shape and minimal surface finish. The only downside of this process is its high production cost. If you’re a renowned company, you’ll want to invest in high-quality carbon steel investment castings.