Yin amfani da mashin ɗin CNC hanya ce mai kyau don ƙirƙirar ainihin abubuwan haɗin gwiwa

Wanda aka bugaAdmin

Yin amfani da mashin ɗin CNC hanya ce mai kyau don ƙirƙirar ainihin abubuwan haɗin gwiwa, ko kuna kera mutum-mutumi ko yin kayan aikin likita.Koyaya, yana da mahimmanci a fahimci tsarin ƙira kafin ku fara sarrafa wani sashi.Wannan zai taimaka muku don tabbatar da cewa kuna samun mafi kyawun aiki.Da farko, kuna buƙatar yanke shawarar girman girman sashin ku.Girman zai dogara ne akan yadda hadaddun abubuwan ke cikin sashin.Girman girma, yawan lokacin da ake ɗauka don kera sashin.CNC machining iya aiki tare da iri-iri na kayan, don haka za ku so ku yi la'akari da abin da irin kayan aiki zai yi aiki.Da zarar kun tantance girman sashin ku.za ku buƙaci yanke shawara akan kayan aiki mai dacewa.Kayan aiki na iya zama kayan aiki mai ban sha'awa ko kuma ƙarshen niƙa.Za ku kuma so ku yanke shawara idan kuna son samun kayan aiki na musamman don wasu nau'ikan ramuka.Gabaɗaya, ƙaramin kauri na bangon kayan injin CNC yakamata ya zama kusan mm 1.5 don robobi da 0.8 mm don karafa.Wannan ƙaramin kauri ne wanda zai ba da damar sarrafa sashin daidai gwargwado.Idan bango ya fi sirara, sashin zai iya zama mai saurin girgizawa da karyewa.Ganuwar bakin ciki kuma na iya rage madaidaicin sashin, haɓaka farashi da lokacin sarrafawa.Wani abu da za a yi la'akari da lokacin da za a yanke shawara a kan wani sashi na CNC shine haƙuri.Wannan yana nufin kewayon girma da aka yarda.Yawancin shagunan na'ura na CNC za su yi amfani da juriya na gaba ɗaya, kamar +/-.005 inci, amma kuna son tabbatar da bincika mashin ɗin ku game da ƙayyadaddun bayanai.Wani abu da za a yi la'akari shi ne siffar ɓangaren.Misali, kuna iya yin la'akari da ƙara fayiloli zuwa kusurwoyin wani sashe don haɓaka aikin injina.Koyaya, zaku so ku guje wa kusurwoyi masu kaifi da bakin ciki, saboda waɗannan na iya zama da wahala a injin.Za ku kuma so ku tabbatar da cewa fasalulluka a ɓangarenku an gina su da kyau.Ƙananan kuskure na iya haifar da samfur mara aiki ko kuskuren likita.Wannan gaskiya ne musamman idan kuna kera wani sashi don masana'antar likitanci.Hakanan ana buƙatar tantance girman ramukan.Ya kamata ramuka su kasance aƙalla 2.5 mm a diamita don ba da ɓangaren daidaitattun daidaito.Idan rami ya fi wannan girma, yana iya buƙatar kayan aiki na musamman don mashina.Idan ba ku da tabbas game da sarƙaƙƙiyar ƙirar ku,za ku iya amfani da zane-zane na fasaha don taimaka muku wajen bincika juriyarku.Wannan zai cece ku lokaci mai yawa da ƙoƙari, da kuma taimaka muku don sadarwa mafi kyau tare da mashin ɗin ku.Hanya don nemo kamfanin injina shine neman takaddun shaida na ISO.Wannan zai tabbatar da cewa kuna aiki tare da kamfani wanda ke da ƙwararrun injiniyoyi a hannu don magance duk wata matsala ta inji.Hakanan zaka iya tambaya a kusa da neman shawarwari.Wani ƙwararren kamfani kuma zai sami kayan aikin ci-gaba a hannu.

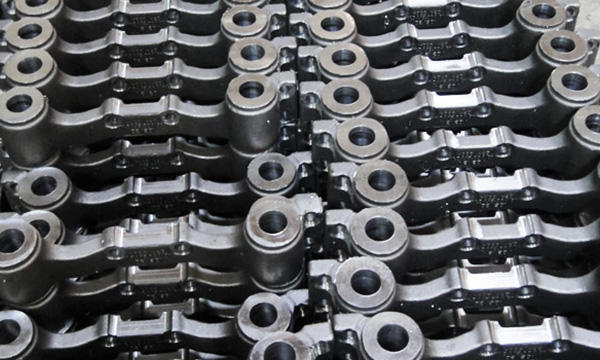

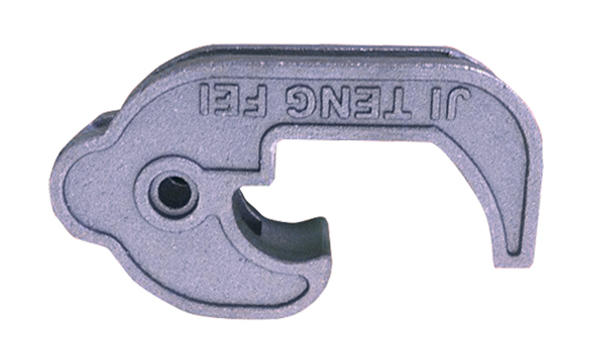

CNC Machining Juya Custom CNC Bakin Karfe Part Mountain Bike Parts

| abu | machining sassa |

| Wurin Asalin | China Zhejiang |

| Sunan Alama | nbkeming |

| Lambar Samfura | KM-M006 |

| Kayan abu | Carbon karfe, gami karfe, bakin karfe |

| Girman | Musamman bisa ga buƙatun abokin ciniki |

| Siffofin | OEM sarrafa gyare-gyare |

| Amfani | Sassan motoci, injinan noma, injinan gini, samfuran ƙarfe, samfuran ƙarfe na waje, sassan ruwa |